If you’ve been following along with Project E21, you probably know by now that things rarely go according to plan. Part 1 was about falling down the rabbit hole. Part 2 was a war against grime and regret. Part 3 brought an engine swap that almost, but not quite, worked. And here we are at Part 4: a tale of moving cross-country (again), buying another new engine off Facebook Marketplace, and steam-cleaning my way into an existential crisis. Because what’s a good project car without at least one “what have I done?” moment every few months?

A Change of Scenery (Again)

Let’s start with the life stuff.

After a stint in Austin chasing new opportunities and warmer winters, life did what life tends to do: it got complicated. Long story short, jobs shifted, priorities reshuffled, and my wife and I decided it was time to head back to Reno, Nevada, where we grew up. The decision was simple on the surface, but it felt huge. Time for more friends and family, and a new area to explore car culture. But honestly, it felt like a needed reset. New city (again), new mindset, and maybe, just maybe, a new chance to finally get this E21 running. Like actually running.

Why I Gave Up on Carbs

You know what doesn’t like altitude? Carburetors. You know what doesn’t like cold mornings, hot afternoons, unpredictable throttle response, and literally anything other than a dyno-tuned, sea-level fantasy world? Also carburetors.

When I first swapped in the M10B18, I thought I was being clever. Keep it old-school. Keep it analog. Keep it “fun.” But the reality is that I was spending more time trying to get the car to idle than actually driving it. And when I moved back to Reno, 4,500 feet above sea level, everything got worse. Cold starts? Nightmare. Tuning? Impossible. Fun? Nowhere to be found.

At a certain point, you have to stop fighting the car and start working with it. The solution? Fuel injection. And if I were going to switch, I might as well do it right. And that’s where engine swap #2 comes in, but this time we are embodying the words of M539 Restorations‘ Sreten: Keep it Classy, Keep it OEM.

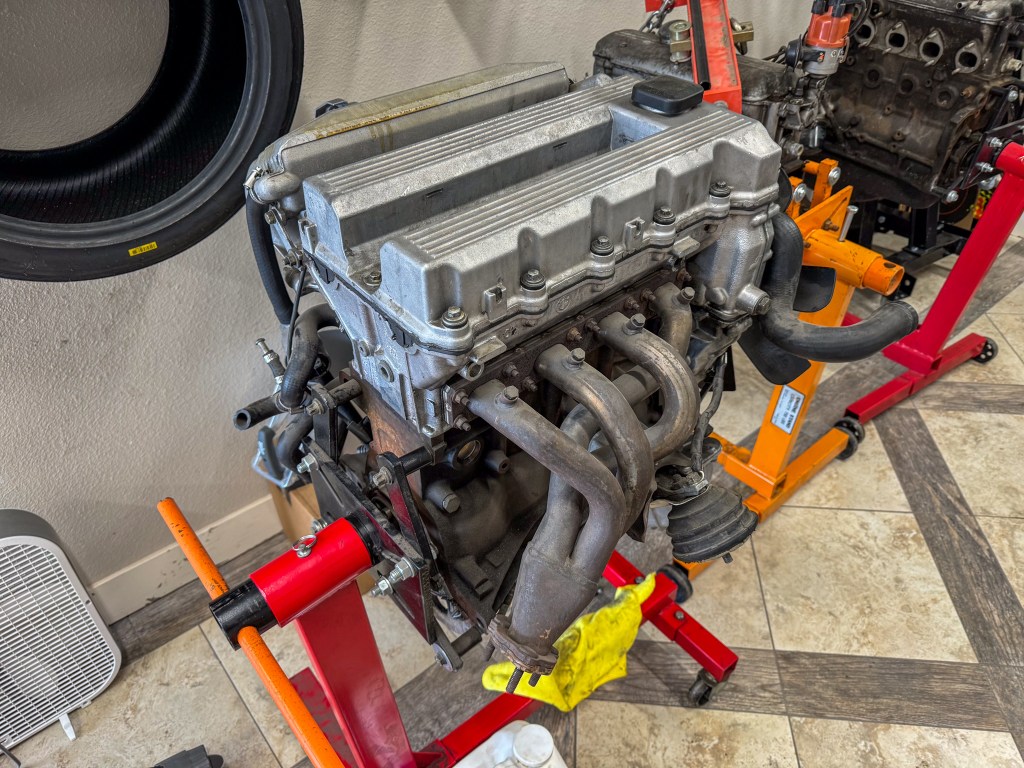

I landed on the M42 after too many nights doomscrolling forums and falling deep into the BMWBlog wormhole. The short and sweet is it’s a 1.8L DOHC inline-four that came in the E30 318is. Light, efficient, rev-happy, and modern enough to actually work without prayer. Plus, the M42 uses Motronic 1.7 fuel injection, more reliable, more tunable, and way less headache. In fact, outside of engine mounts, I only need to swap 6 wires in the engine harness to plug right into the stock E21 body harness. Its a very simple swap that won’t keep me up at night. There is an exceptional writeup on the swap from Straight Six Bimmers, if you are out there somewhere, thank you for saving my life. However, the problem is finding an E30 specific M42.

Why the M42 is the Perfect Engine (Right Now)

The M42 isn’t rare, but it’s trending in the right direction. These engines used to be junkyard fodder, but lately, people are waking up to their potential. They’re not as exotic as an S14 or as torquey as an M20, but for light chassis cars like the E21, the M42 hits a sweet spot: lightweight, rev-happy, and relatively simple to work on. If you’re looking to bring your 70s or 80s BMW into the modern-ish era without sacrificing character, the M42 is a smart move. It’s just modern enough to work, just old-school enough to keep things interesting.

Finding one wasn’t hard, but it also wasn’t easy. These engines are becoming harder to source as they’ve gained popularity as swaps for less powerful BMWs like 2002s. But the stars aligned when a guy in Sacramento listed a full pullout, engine, transmission, wiring harness, ECU, driveshaft, AFM and all, for a shockingly reasonable price of $1200. It had been sitting in a garage waiting to be swapped into his 2002, but was put on the back burner as he had a lead on an S52 and decided to go that route. I was all in.

Cue the late-night drive from Reno to Sacramento. Red bulls in hand, trailer in tow, Spotify locked on some nostalgic late 2000s playlist. The seller was exactly who you’d hope to meet in a Facebook Marketplace transaction: chill, honest, and maybe a little too eager to talk about his next Miata project. The motor looked solid. Compression was good. No cracked timing case (a known M42 pain point). We shook hands, loaded it up, and I made the 3.5-hour drive back grinning like a kid who just bought his first Game Boy.

It would be a bit before I could get the M42 fully installed, but acquiring it is a feat in itself these days. The swap is going to require some fabrication, so I managed to place the motor in the engine bay at least with the help of an engine hoist. The motor is now out of my way and sitting relatively where it should in the bay. I;ll be taking some measurements and mocking up some engine mounts. Once that is completed, the engine will be ready for wiring and full installation. Its closer to being installed than it looks at the moment. But unfortunately, I have bigger problems.

The Rust Revelation

Now for the bad news.

After getting the new engine home and spending the better part of a weekend reorganizing the garage, I figured I’d reward myself with a quick interior cleanup. Pull the seats, vacuum the floors, maybe hit it with a little steam clean.

Worst idea I’ve ever had.

Under the carpet, under the sound deadening, and under my carefully constructed delusion that this car was “pretty solid,” I found rust. A lot of it. Like “is this still structurally sound?” levels of it. Front jacking points and floor pans on both sides, as well as a good chunk of the inner rocker panel, were all swiss-cheesed in a sea of crusty, crunchy, orange destruction. I stood there with the steam cleaner still running and just stared at it. There’s a moment every project car owner dreads where you wonder if it’s time to just walk away. This was mine. But after a little sulking and a lot of research, I decided I wasn’t ready to give up. I started ripped up the carpet and any panels to find where the rust ended. Unfortunately, that ended up being most of the interior as the rust was up into the front sills and would require a lot of cutting. In an effort to keep my interior from catching fire from all of the welding and grinding, most of it was removed.

My neighbor had some previous welding skills and convinced me we could tackle it. I did the logical thing and headed to Harbor Frieght to buy a new welder. After some “lessons” in my garage on some old rusted metal we cut out, I felt I was ready enough to try it on the car. I sourced some reproduction panels from Wallothenesch.com and Valcas Garage. I took my time as I wanted to do this fix once and only once. To be honest, there was no real rush as the car wasn’t going anywhere.

After hours of problem-solving, cutting, grinding, welding, and sanding, I eventually figured out a solution and got the pans installed. IT WAS A NIGHTMARE. While they aren’t perfect, I’m insanely proud of the work I was able to accomplish, even though it isn’t high quality. The ethos for this project quickly became “Perfection is the enemy of good enough”. Fixed and working now, it’s much better than perfect later. All that matters is that the floors are fixed and ready for another 40 years of driving.

However, I will leave this part a little sparse on details, as I will be posting a deep dive into my welding adventure in an upcoming article. I’ll show all of the cut sections and the final results. But for now, I want to leave you with the fact that projects like this are not that crazy to tackle on your own. You just need to have a determined mindset and work through the problems, no matter how large they are. Everyone starts somewhere, just gotta dive in and get to it.

Looking Ahead

So where does that leave us?

Project E21 has officially entered the “over the hump” stage of the pivoted engine swap. The M42 swap is sitting in the engine bay, but not actually installed, while it waits for some engine mounts. The floor rust is fixed and in need of some tidy-up before I put the interior back in. And my garage is now home to more tools than uninstalled car parts. Weirdly, this is the most fun I’ve had with the project so far. Every setback has pushed me to learn something new, to take the next step, and to keep the dream alive, even when it’s buried under three layers of rust and questionable decision-making.

Next up: welding horror stories, questionable fabrication techniques, and a deep dive into why they call rust “car cancer”.

Until then, thanks for sticking with me. The road ahead is full of work, but also full of promise. I can’t wait to share more updates as I continue with the swap and take steps toward getting the E21 ready for its first M42-powered trip. Stay tuned, because the best chapters are yet to come.

Leave a Reply