The wheel industry has a problem. It’s drowning in marketing buzzwords, corporate acquisitions that strip away soul, and products designed by committee rather than enthusiasts. Enter AlterMann, a company that’s doing something radical: cutting through the nonsense and building custom forged wheels the way they should be built.

Based in Westminster, California, AlterMann isn’t trying to reinvent the wheel. They’re just making damn good ones without the typical industry garbage. Custom three-piece forged construction, sizes from 13-inch up, and a philosophy that reads more like a conversation with a car guy at a track day than a corporate mission statement.

In this piece, we’re diving into what makes AlterMann different in a sea of sameness, breaking down why three-piece forged wheels are worth understanding, exploring their deep connection to VW culture and the broader enthusiast community, and examining whether genuine passion still has a place in today’s consolidated aftermarket. If you’re tired of wheel companies that feel more like marketing agencies than manufacturing shops, this story’s for you.

The Rotiform Legacy

To understand AlterMann, you need to understand where it came from. Jason Whipple co-founded Rotiform with Brian Henderson, starting with two wheel designs: the traditional Y-spoke MIA and the Lamborghini LP560-4-inspired BLQ. That second one became the foundation of their success, and they didn’t even hide the inspiration, naming it after Bologna airport’s code.

What started in a Compton warehouse grew into a global powerhouse that practically defined the modern wheel scene. Rotiform’s three-piece forged offerings, with infinite customization for offset, lip width, and finishes, set a new standard for what enthusiasts could expect.

But success breeds complications. Corporate acquisitions and shareholder demands tend to dilute the passion that built companies in the first place. If you’ve been following the WheelPros/Hoonigan drama in the automotive world, you’ll already know why Jason’s Rotiform days are in the rearview. I am not here to tell that story, but let’s just say when original founders walk away to start fresh, it tells you everything about what happened to the company they built.

Jason’s decision to launch AlterMann represents a return to first principles: car guys making car wheels for car guys. Doesn’t have to be more complicated than that.

What is AlterMann?

Visit AlterMann’s website and you’re immediately hit with something refreshing: Honesty. “Do you really want to know? We’ll just skip the typical bull about how we engineer this or curate that and all the laser guided ultra precision computer controlled AI generated gibberish you see these days. We are old. We’ve been there and done that.”

Their pitch is simple: custom forged 3, 2 and 1-piece wheels from 13-inch up, handling everything from vintage builds needing period-correct sizes to modern track builds requiring precise specifications. It’s a full-service setup, even rebuilding and refinishing wheels you already have. Pure love of wheels, period.

The wheel industry has split between ultra-budget cast wheels that prioritize price over everything and ultra-premium options that price out most enthusiasts. AlterMann occupies the middle ground: serious engineering combined with genuine understanding of automotive culture and realistic pricing for enthusiasts who are serious about their builds but don’t have unlimited budgets or six-month lead times. This is what separates companies run by enthusiasts from companies run by spreadsheet warriors.

No Showroom Needed

Step into AlterMann’s Westminster, California shop, and the first thing that hits you is how surprisingly small it is for the level of work happening here. Natural light pours in through the open garage door, illuminating what can only be described as organized chaos. This isn’t some sterile showroom. It’s a real workshop.

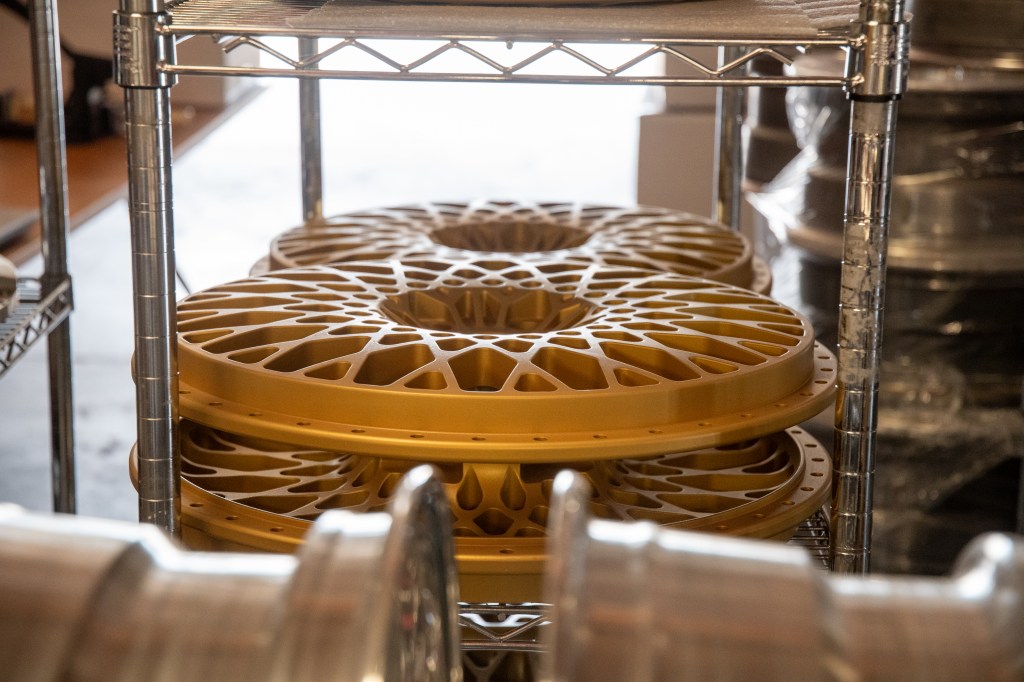

Wheel racks line the center of the shop, filled with recently machined faces waiting for assembly. Stacks of barrels in various stages of completion sit organized by order, some raw, others polished to a mirror finish, each tagged and ready for the next step in the process. In the corner, completed wheel sets sit wrapped on pallets, ready to ship out to customers who’ve been waiting for their custom builds.

Two four-post lifts dominate the limited floor space, and on them sit the kind of builds that tell you everything about Jason’s priorities. A couple of Golf projects in various stages of completion share space with a Scirocco painted by Conifer, each one a testament to VW culture and the community AlterMann serves. These aren’t customer cars waiting for wheels. These are Jason’s personal projects, the builds that inspire the work and keep the passion alive.

Even Jason’s office reflects this ethos. It’s a humble space tucked into the shop where a VAG 1551 diagnostic tool sits on the shelf next to multiple prototype wheels, technical drawings scattered across the desk, and the tools of someone who actually uses them rather than displays them. No fancy furniture. No corporate branding. Just the workspace of someone focused on making good wheels, not looking like he’s trying to make good wheels.

The shop’s compact footprint makes the output even more impressive. In this surprisingly small space, Jason hand-assembles every wheel, spending about an hour per wheel to ensure nothing is out of spec or out of round in any axis. It’s meticulous work happening in a modest environment, proving that world-class craftsmanship doesn’t require a massive facility or corporate infrastructure. Simple and good, nothing more.

Three-Piece Engineering Explained

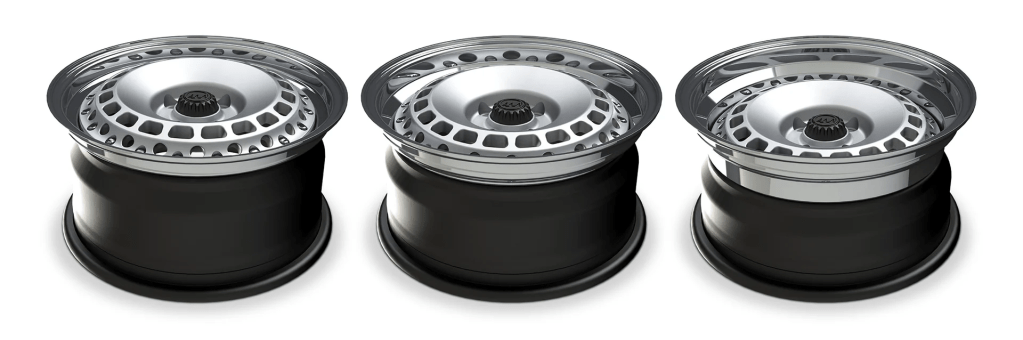

Three-piece wheel construction has roots in motorsport, born from the need to rebuild damaged wheels quickly and customize specifications for different tracks. The concept is elegantly simple: a center section, an inner barrel, and an outer barrel, all bolted together. Race teams could swap barrels to change offset or width without replacing the entire wheel, a practical solution that eventually became the foundation for some of the most iconic wheel designs in automotive history.

The real magic lies in infinite customizability. Need a specific offset that doesn’t exist in any catalog? The barrel depth can be sized exactly to your requirements. Want a particular lip width for perfect flush fitment? The outer barrel gets machined to whatever your build demands. Dreaming of a finish combination nobody else has? Each component can be treated separately.

This is where AlterMann separates itself. Single-piece forged wheels can be lighter, but they require expensive molds for each size and offset combination. Manufacturers need volume to justify production, so you get what they decide to make. AlterMann’s specialty is the one-off custom build. No molds required. No minimum order quantities. Want 15×8 with +32 offset in a specific finish? They’ll make it. Need something obscure for a vintage application nobody else will touch? That’s exactly what they’re set up to do.

As mentioned, Jason hand-assembles every wheel himself, spending about an hour per wheel to ensure nothing is out of spec or out of round in any axis. It’s meticulous work that most companies have automated away, but it’s the difference between a wheel that’s technically correct and one that’s genuinely perfect. Every wheel gets hand-engraved with a unique serial number documenting every specification. This isn’t mass production. It’s bespoke engineering for people who understand that proper fitment isn’t about what’s popular, it’s about what’s right for your specific application.

Why Wheels Matter More Than You Think

Wheels are the only modification that affects literally every aspect of your car’s performance and appearance. Change your wheels and you’ve changed acceleration, braking, handling, ride quality, fuel economy, and aesthetics all at once.

The physics are unforgiving. Reducing unsprung weight at the wheels has multiplicative effects that cascade through the entire vehicle. Shaving five pounds off each corner doesn’t just reduce total weight by twenty pounds, it reduces the rotational inertia your engine fights during acceleration and your brakes fight during deceleration. Wheel design also affects brake cooling, which directly impacts stopping power and fade resistance.

Aesthetically, wheels define a car’s personality more than any other single modification. You can dump thousands into suspension, engine, and interior work, but if the wheels don’t work with the overall design, the entire build feels disconnected. Get the wheels right, and everything else falls into place.

This is why companies like AlterMann matter. They understand wheels aren’t just round things that hold tires. They’re the foundation upon which great builds are constructed, and every offset decision, finish choice, and sizing consideration ripples through the entire project.

VW Culture and Community

Here’s where AlterMann gets interesting. They’re a VW-first brand that embodies the “for the people, by the people” ethos, which is ironic given Volkswagen literally means “people’s car” in German. But the VW scene has always been about more than just cars. It’s a culture built around ingenuity, community, and the belief that good design should be accessible rather than elitist.

Whether you’re rolling a slammed Jetta on coilovers or building a Porsche 911 track weapon, you’re part of the same community that values engineering excellence over badge snobbery. AlterMann taps directly into this culture by understanding that wheels aren’t just products. They’re cultural statements. The right set of wheels can define an entire build, influence a scene, and shape the direction of automotive enthusiasm.

AlterMann builds wheels for the community, not just customers. Their approach is about contributing to conversations, building relationships with builders, and understanding what enthusiasts actually need. It’s organic engagement by people who are genuinely part of the scene, creating a feedback loop where enthusiasts get products that meet their actual needs and the broader community benefits from having a company that actively supports automotive enthusiasm.

Authenticity Always Wins

AlterMann exists because someone decided the automotive aftermarket needed less corporate speak and more genuine craftsmanship. In an industry increasingly dominated by consolidation and committee decisions, they’re betting that enthusiasts will support a company that prioritizes custom solutions over catalog products and community relationships over quarterly earnings.

The early signs suggest that bet is paying off. AlterMann’s foundation in three-piece forged construction gives them the flexibility to build one-off custom wheels that larger manufacturers can’t justify. Their roots in VW culture and motorsport history provide authenticity that can’t be manufactured. Their willingness to tackle obscure specifications and vintage applications fills gaps that mass-market companies ignore.

Whether you’re building your first project car or your fifteenth, the wheels you choose define how your car performs and how it’s perceived. AlterMann exists to ensure that choice doesn’t require compromise. They might be a little rough around the edges, but in an industry where authentic enthusiasm is becoming increasingly rare, that’s exactly what makes them worth paying attention to.

Let’s hope my E21 can become reliable enough to meet up at AlterMann for a new set of wheels. Until then, I’ll be here, cheering on one of the best companies in the automotive aftermarket, hands down.

Leave a Reply